Admin:jarrun Data:2024-07-17 16:49 Number of views :

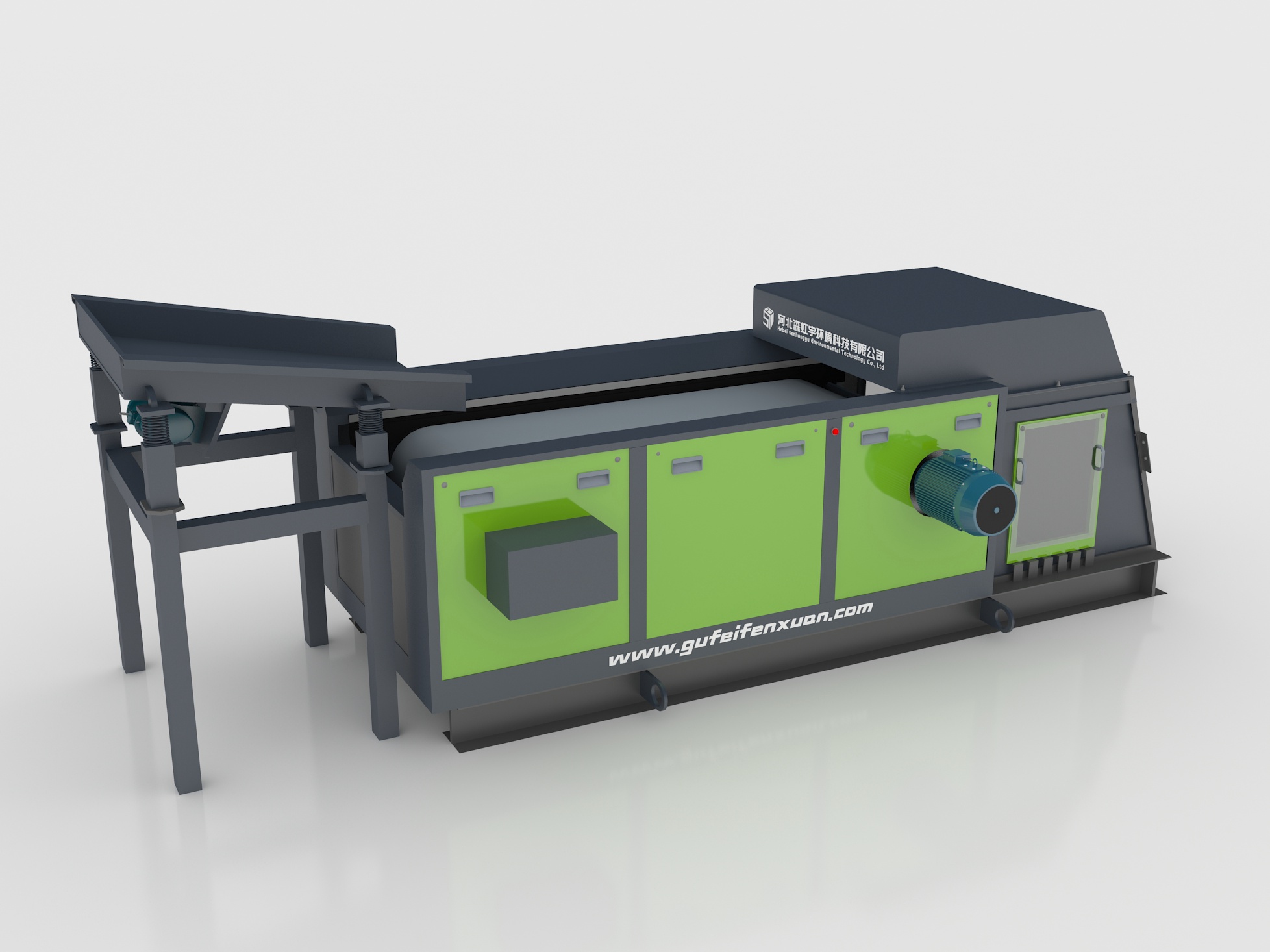

Eddy current separator, also known as non-ferrous metal separator, is mainly used in solid waste tailings to separate non-ferrous metals such as copper, aluminum, zinc, tin, gold and silver.

Eddy current separators use the different electrical conductivity of various substances to carry out sorting. The sorting principle is to use a magnet rotor composed of magnets to generate an alternating magnetic field during rotation, so as to achieve the purpose of separation. Eddy currents are induced in the metal when a metal with electrical conductivity is passed through a magnetic field. The eddy current itself will generate an alternating magnetic field, which is opposite to the magnetic field generated by the rotation of the magnet rotor. Separation of non-metallic substances such as plastics.

Eddy current separator features:

1. The bearing is protected by sealing, which can adapt to the harsh environment with heavy dust.

2. The main shaft bearing is equipped with temperature control display, which is cooled by coolant to avoid overheating, and the bearing has a long service life.

3. The main shaft has thermal protection function, it will automatically trip if the temperature is too high, and will not damage the bearing.

4. The permanent magnet NdFeB is used as the magnetic source, and the magnetic performance is stable and lasting.

5. The magnetic roller of the eddy current separator adopts an eccentric type, and the position of the magnetic pole is adjustable.

6. The frequency conversion control is adopted, and the belt speed is adjustable.

7. The sorting particle size range is large.

8. The equipment has low energy consumption, stable operation and economical benefits.

Phone

YouTube